PRODUCT

- Biological Safety Cabinet

- Air Protection Products

- Refrigerator and Freezer

-

Clinical & Analytical Instruments

- Fluorescence Immunoassay Analyzer

- Blood Coagulation Analyzer

- Vein Finder

- Auto ESR Analyzer

- Automatic Chemiluminescence Immunoassay System

- Auto ELISA Processor

- ATP fluorescence detector

- Electrolyte Analyzer

- PH meter

- Visible Spectrophotometer

- Hematology Analyzer

- Chemical Analyzer

- Nucleic Acid Extractor System

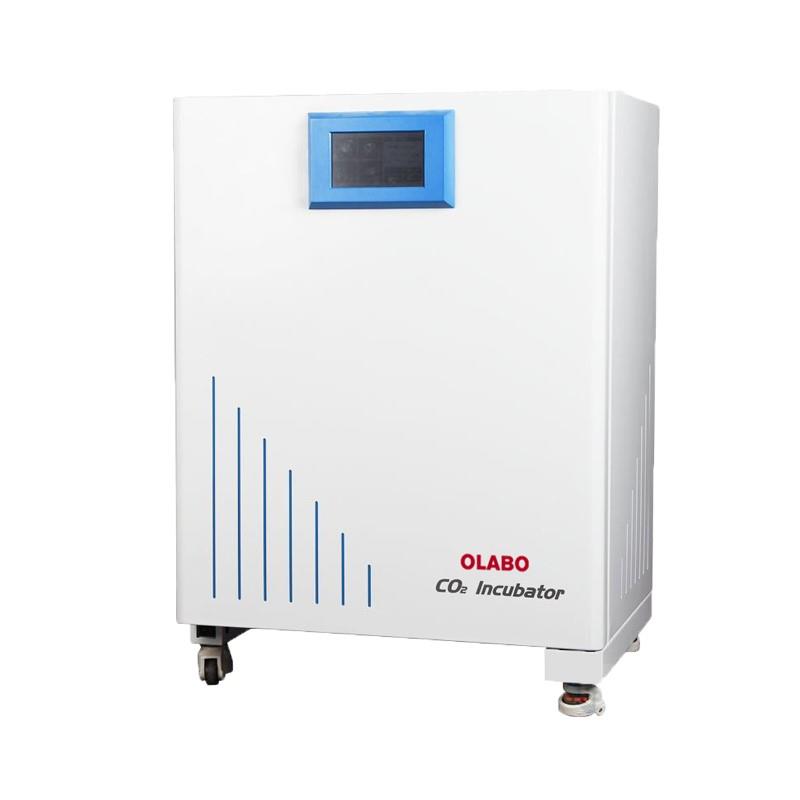

- Incubator and Oven

- Disinfection and Sterilization Equipment

- Epidemic Prevention Products

-

General Lab Equipment

- Kjeldahl Nitrogen Analyzer

- Cell Thawing Instrument

- Wastewater Treatment System

- Washer Disinfector

- Single Punching Machine

- Tissue Grinding Machine

- Laser Airborne Particle Counter Tester

- Graphite Digester Instrument

- Peristaltic Pump

- Tablet Friability Tester

- Slide Dryer (Hot Plate)

- Constant Temperature and Humidity Weighing Cabinet

- Disintegration Tester

- Elisa Microplate Reader

- Medical Sealing Machine

- Electric pneumatic hemostatic

- Microscope

- Hydrogen Generator

- Viscometer

- Elisa Microplate Washer

- PCR Instrument

- Water Purifier

- Centrifuge

- Rehabilitation Products

- Medical Equipments

- Cold Chain

- Sample Processing