2. HOW?

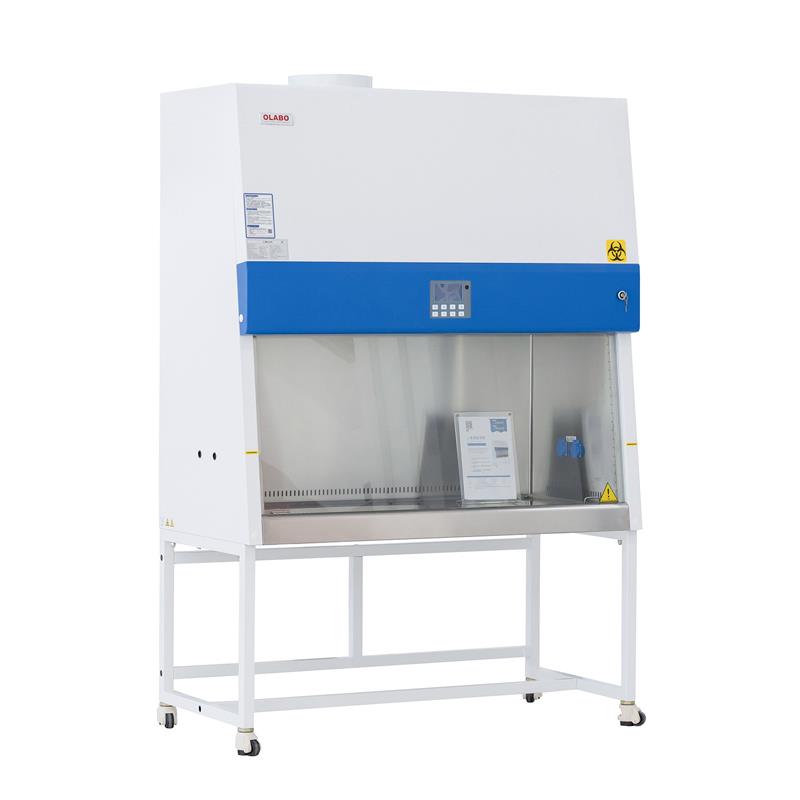

Class I biological safety cabinet

The Class I BSC was the first recognized BSC and, because of its simple design, is still in wide use throughout the world. It has the advantage of providing personnel and environmental protection and can also be used for work with radionuclides and volatile toxic chemicals. Because unsterilized room air is drawn over the work surface through the front opening, it is not considered to provide consistently reliable product protection.

Class II biological safety cabinets

As the use of cell and tissue cultures for the propagation of viruses and other purposes grew, it was no longer considered satisfactory for unsterilized room air to pass over the work surface. The Class II BSC was designed not only to provide personnel protection but also to protect work surface materials from contaminated room air. Class II BSCs, of which there are four types (A1, A2, B1 and B2), differ from Class I BSCs by allowing only air from a HEPA-filtered (sterile) supply to flow over the work surface. The Class II BSC can be used for working with infectious agents in Risk Groups 2 and 3. Class II BSCs can be used for working with infectious agents in Risk Group 4 when positive-pressure suits are used.

Selection of a biological safety cabinet

A BSC should be selected primarily in accordance with the type of protection needed: product protection; personnel protection against Risk Group 1–4 microorganisms; personnel protection against exposure to radionuclides and volatile toxic chemicals; or a combination of these. The table below shows which BSCs are recommended for each type of protection. Volatile or toxic chemicals should not be used in BSCs that recirculate exhaust air to the room, i.e. Class I BSCs that are not ducted to building exhaust systems, or Class IIA1 or Class IIA2 cabinets. Class IIB1 BSCs are acceptable for work with minute amounts of volatile chemicals and radionuclides. A Class IIB2 BSC, also called a total exhaust cabinet, is necessary when significant amounts of radionuclides and volatile chemicals are expected to be used.